Lab automation made easy and affordable

The OT-2 Robot is a high-performance benchtop liquid handler that meets or exceeds the accuracy of other lab robots.

Get started for <$10,000

Access our OT-2 demo video library

TRUSTED GLOBALLY BY OUR PARTNERS

Why automate?

REPRODUCIBLE METHODS

Easily replicate your results and share optimized protocols with lab automation.

MAXIMIZE TIME

Reallocate lab time to data analysis, experiment design, and communicating results—NOT manual pipetting.

REPLICATE PROTOCOLS

Load & modify customer-verified protocols and let the robot run them, end-to-end.

MINIMIZE HUMAN ERROR

Robots don't get tired or distracted. Eliminate this source of error.

Lab automation myths busted

“We don’t do enough pipetting to invest in an automation tool.”

Scenario

A researcher in the department of pediatrics at an academic research center builds next-generation sequencing libraries. She is the only person in her lab pipetting, and she doesn’t think she moves enough liquid to invest in a liquid handler.

Reality

The best way to determine if an automated liquid handler can benefit your operation is to calculate how much time pipetting takes in your lab. Include all pipetting steps, the logistics of moving samples to and from equipment, time to adjust plates and labware, and even interruptions and distractions in workflow. Many labs underestimate how much bench time they spend on these tasks, undercounting how frequently tedious tasks such as prepping a PCR plate, doing a DNA extraction, and plating cell media are done on a daily, weekly, monthly, and even yearly basis.

“Liquid handlers don’t get used often— and that’s money wasted.”

Scenario

A principal investigator plans to expand the number of researchers in her academic lab, but is hesitant to purchase a liquid handler because it might not be used.

Reality

Why might lab automation tools go unused? As many as 25 percent of labs using these tools are engaged in highly complex projects that take time to activate, and labs may not have the time to set up these tools. Also, some automation solutions are only set up to do one protocol, making it difficult or even impossible to switch applications when needed by the lab. Other tools are so complicated that only one or two members of the lab have the expertise to use them, causing all lab members to rely on those few to keep the tools running. And, frankly, some workflows just can’t be automated, which is a tough reality to accept after a robot is gathering dust in the lab.

“Manual pipetting is more accurate than a liquid handler.”

scenario

The chief scientific officer at a therapeutic biotechnology company is diluting her samples before purifying the isolated DNA samples. She has been pipetting for more than a decade with relatively reproducible results, and does not want to lose that accuracy by using a liquid handler.

reality

A quality automated liquid handler can achieve most of the nuances of manual pipetting, including speed, volumes, aspiration settings, tip positions, incubation times, pause steps, tip touch, and blowouts—every single time. Once the tool is properly set up and calibrated, human error decreases, and the speed, accuracy, and reproducibility of conducting experiments increases“Liquid handlers are too complicated to incorporate into my lab.”

scenario

A senior researcher at a cancer research center studies tumor immunology. His team is considering a liquid automation tool to automate qPCR preps, but he is concerned because most liquid handlers on the market will be very complicated to incorporate.reality

It’s true that many liquid handlers are based on complicated, decades-old designs that require installation and training from the manufacturer, and highly technical skills to set up. In contrast, newer liquid handling robots tend to be designed around the user experience. You can install them. You can set them up. You can control them. You can learn how to use and integrate them into your workflows. You might even be able to get your protocol up and running within 24 hours. All by yourself.“Liquid handlers require too much time to set up and learn to use.”

scenario

A senior researcher at a genomics company has designed a multi-step protocol that uses PCR to amplify DNA from patients. It is precise and tailored to the lab, and the researcher needs to ensure that any automation equipment supports that protocol. Sticking with the manual process just seems easier.reality

Once it’s correctly integrated into your workflow, an automated liquid handler allows for greater accuracy at each liquid handling step because it minimizes human errors. It increases throughput and enables efficient workflow scale-up. It also gives you an accurate record of exactly what happened to your samples during your experiment, facilitating much more sophisticated analyses.“I must learn programming to use a liquid handler.”

Scenario

A microbiologist in an industrial pharmaceutical lab runs ELISA assays as part of his drug discovery workflow. It takes 12 hours and is tedious and painful on his hands and back, so he’d like to automate, but he doesn’t have coding experience or time to learn.

reality

While you certainly will need to learn to set up, calibrate, and program your liquid-handling robot, you won’t need to spend time becoming an IT expert to enjoy saving time and achieving reproducible, consistent results that make your lab a more competitive player in your industry.“One lab automation tool can’t run multiple protocols.”

scenario

A scientist at a genomics company has created a serial dilution protocol using an automation tool. Others in her lab have developed a multi-step PCR prep protocol. The lab wants to automate both protocols on the liquid handler.reality

As opposed to handling liquids manually, automation gives you much more flexibility to tweak your protocols every day. Just like any other tool, when you learn how to use it, you won’t be limited by it—you’ll grow with it. Once you’ve set up a new protocol, all you have to do is sterilize, load the new settings, put the labware and samples in the same slots, and you’re ready to go. Even if it takes time to switch your protocols, robotic automation reduces user error and contamination, improves repeatability, and gives you the unique ability to collect more data with new, high-throughput work.“Liquid handler vendors don’t respond to customers.”

scenario

A scientist at a synthetic biology company using E. coli for industrial purposes was considering a liquid automation tool to accelerate the screening of colonies, but hit a roadblock when tech support fell short of expectationsreality

Before you decide to make your lab automation tool purchase, do your research and explore the support options offered by reputable vendors. Request a referral to speak to a customer whose lab is comparable to yours, and ask about both the tool’s functionality and the vendor’s service reality. And here’s a tip—send an inquiry or call the vendor’s support team during off-hours. The responsiveness may surprise you… and give you a good idea of what to expect moving forward.Flexible, open-source, and user-friendly.

Highly flexible

Configure it to your requirements.

- 11-deck platform with options for Magnetic, Temperature, and Thermocycler Modules

- Swappable single and eight-channel pipettes for multiple volume options

- Standardized (SBS) deck slots work with your existing labware

Outstanding Performance

Accurate and Precise.

- Accuracy: 15% at 1µL

- Precision: 5% at 1µL

- Throughput: Fills a 96-well plate in 22 seconds

User-friendly

Intuitive, and integrates easily.

You can set up and install the OT-2 yourself. It's plug-and-play, with immediate access to protocol libraries. It easily integrates to your existing instruments and is reagent and bead system agnostic.

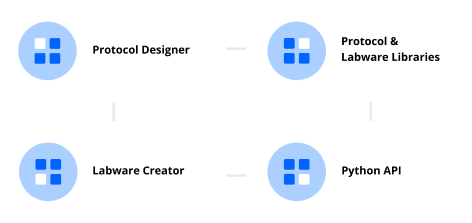

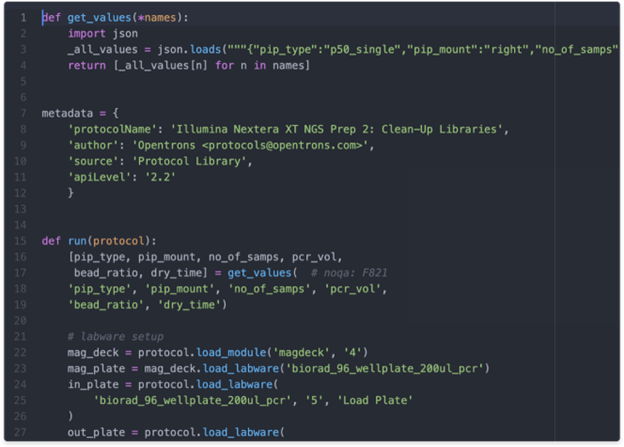

Choose the free protocol you prefer: beginner-friendly or advanced, with powerful cloud-based tools to gain unmatched control of your workflow.

Open source

Customizable control for maximum versatility.

- 100% customizable—you can modify according to your assay

- Use the simple, yet powerful Python AI to modify or customize protocols

- Digital protocol commands surpass manual pipetting

Compact footprint

- 63cm x 57cm x 66cm / 25in x 22.5in x 26in (W,D,H)

- Takes up half of your standard lab bench

Pipette configurations

- Single and 8-channel pipetting

- 2-pipette mounts, for a configuration of 1 or 2 single or 8-channel pipettes. Pipettes are easily interchangeable.

Pipette volumes and specs

- Single channel: 1-1000µl

- 8-channel: 1-300µl

- Opentrons Pipette Whitepaper (GEN1 & GEN2) ›

- Single channel manual ›

- 8-channel manual ›

Deck

- 11 deck slots enable countless configurations

- Deck slots are compatible with standard SBS dimensions. Deck also includes a removable trash bin.

Connectivity

- WiFi 2.4 GHz IEEE 802.11b/g/n, USB 2.0

- Learn more ›

Weight

- 48kg or 105.8 lb

Video

- Integrated video camera (Included for future or custom functionality)

Audio

- Integrated audio system (Included for future or custom functionality)

Power Requirements

- Robot Power Input: 36VDC, 6.1A

- Power Adapter Input: 100-240VAC, 50/60Hz, 4.0A/115VAC, 2.0A/230VAC

- For additional power requirement information, please review this support article

Frame composition

- Rigid steel and CNC aluminum design

Operating Temperature & Relative Humidity

- Recommended 20-24C Recommended 40-60% RH

- Learn more ›

Speed

Fills a 96-well plate in 22 seconds

| Pipette | Distribute, One Tip |

Transfer, Same Tip |

Transfer, New Tip |

|---|---|---|---|

|

P20

8-channel

|

0:22 | 1:35 | 4:19 |

|

P300

8-channel

|

0:26 | 1:38 | 4:24 |

|

P20 Single

|

3:12 | 13:10 | 36:01 |

|

P300 Single

|

4:01 | 13:39 | 41:31 |

|

P1000 Single

|

5:54 | 15:21 | 44:50 |

Accuracy and precision

Single and 8-channel pipetting

| Pipette | Volume | Random Error | Systematic Error | ||

|---|---|---|---|---|---|

| %D | µl | %CV | µl | ||

| p20 | 1 | ±15% | 0.15µL | ±5% | 0.05µL |

| 10 | ±2% | 0.2µL | ±1% | 0.1µL | |

| 20 | ±1.5% | 0.3µL | ±0.8% | 0.16µL | |

| p300 | 20 | ±4% | 0.8µL | ±2.5% | 0.5µL |

| 150 | ±1% | 1.5µL | ±0.4% | 0.6µL | |

| 300 | ±0.6% | 1.8µL | ±0.3% | 0.9µL | |

| p1000 | 100 | ±2% | 2.0µL | ±1% | 1µL |

| 500 | ±1% | 5.0µL | ±0.2% | 1µL | |

| 1000 | ±0.7% | 7.0µL | ±0.15% | 1.5µL | |

| Pipette | Volume | Random Error | Systematic Error | ||

|---|---|---|---|---|---|

| %D | µl | %CV | µl | ||

| P20 | 1 | ±20% | 0.2µL | ±10% | 0.1µL |

| 10 | ±3% | 0.3µL | ±2% | 0.2µL | |

| 20 | ± 2.2% | 0.44µL | ±1.5% | 0.3µL | |

| P300 | 20 | ±10% | 2.0µL | ±4% | 0.8µL |

| 150 | ±2.5% | 3.75µL | ±0.8% | 1.2µL | |

| 300 | ±1.5% | 4.5µL | ±0.5% | 1.5µL | |

Sterility

Full polycarbonate enclosure designed to limit exposure. The OT-2 is not a sterile environment

Add the Opentrons HEPA Module, or add your own UV lights

Viscosity

For best practices on automating viscous liquid handling, review our application note

API compatibility

- Interfaces with any product that has an API

- Opentrons software is open-source and users can make adjustments to the software as needed to interface with other products. While all integrations are possible, they all require custom code work i.e. most customers will need to write custom libraries and install software packages that are not shipped with the robot.

- Learn more ›

Interface

- Windows 10, macOS 10.10 or later, Ubuntu 12.04 or later.

- Opentrons App ›

Tip compatibility

- Use Opentrons Tips and Opentrons Filter Tips

- Opentrons guarantees the performance of Opentrons Tips which were specifically designed for the OT-2. The OT-2 was designed to accommodate all universal bore tip types, but tip quality and dimensions can vary significantly so third party tip performance cannot be guaranteed by Opentrons.

Labware compatibility

- Use common labware already in our Labware Library, or add your own

- If your labware fits on the OT-2 but is not in the Labware Library, it can be added by you using our Labware Creator, or by our team.

- Learn more ›

- OT-2 Manual ›

Warranty

- One year warranty against manufacturer defects

- Stress tested to last a minimum of 3 years of full-time use

- Learn more ›

Return Policy

- 60 day, 100% risk free

- Learn more ›

Certifications

- Certifications complete (CE, FCC, NRTL, CB, ISO 9001)

- Not certified/validated (IVD, GMP)

Tip Handling

- Pick up tip

- Drop tip

- Return tip

- New tip (always, never, once)

- More...

Liquid Control

- Aspirate

- Dispense

- Aspirate speed

- Dispense speed

- Blowout

- Touch tip

- Mix

- Air gap

Utility

- Move to

- Delay

- User-specified pause

- Homing

- Comment

Transfer

- Basic transfer

- Volumes > Pipette Volume

- Distribute

- Consolidate

Variable Settings

- Speed

- Volume

- Count

Other

- Dispose

-

Compact footprint

- 63cm x 57cm x 66cm / 25in x 22.5in x 26in (W,D,H)

- Takes up half of your standard lab bench

Pipette configurations

- Single and 8-channel pipetting

- 2-pipette mounts, for a configuration of 1 or 2 single or 8-channel pipettes. Pipettes are easily interchangeable.

Pipette volumes and specs

- Single channel: 1-1000µl

- 8-channel: 1-300µl

- Opentrons Pipette Whitepaper (GEN1 & GEN2) ›

- Single channel manual ›

- 8-channel manual ›

Deck

- 11 deck slots enable countless configurations

- Deck slots are compatible with standard SBS dimensions. Deck also includes a removable trash bin.

Connectivity

- WiFi 2.4 GHz IEEE 802.11b/g/n, USB 2.0

- Learn more ›

Weight

- 48kg or 105.8 lb

Video

- Integrated video camera (Included for future or custom functionality)

Audio

- Integrated audio system (Included for future or custom functionality)

Power Requirements

- Robot Power Input: 36VDC, 6.1A

- Power Adapter Input: 100-240VAC, 50/60Hz, 4.0A/115VAC, 2.0A/230VAC

- For additional power requirement information, please review this support article

Frame composition

- Rigid steel and CNC aluminum design

Operating Temperature & Relative Humidity

- Recommended 20-24C Recommended 40-60% RH

- Learn more ›

-

Speed

Fills a 96-well plate in 22 seconds

Time to fill 96-well plate Pipette Distribute,

One TipTransfer,

Same TipTransfer,

New TipP208-channel0:22 1:35 4:19 P3008-channel0:26 1:38 4:24 P20 Single3:12 13:10 36:01 P300 Single4:01 13:39 41:31 P1000 Single5:54 15:21 44:50

Accuracy and precision

Single and 8-channel pipetting

Single Channel Accuracy & Precision Pipette Volume Random Error Systematic Error %D µl %CV µl p20 1 ±15% 0.15µL ±5% 0.05µL 10 ±2% 0.2µL ±1% 0.1µL 20 ±1.5% 0.3µL ±0.8% 0.16µL p300 20 ±4% 0.8µL ±2.5% 0.5µL 150 ±1% 1.5µL ±0.4% 0.6µL 300 ±0.6% 1.8µL ±0.3% 0.9µL p1000 100 ±2% 2.0µL ±1% 1µL 500 ±1% 5.0µL ±0.2% 1µL 1000 ±0.7% 7.0µL ±0.15% 1.5µL 8-Channel Accuracy & Precision Pipette Volume Random Error Systematic Error %D µl %CV µl P20 1 ±20% 0.2µL ±10% 0.1µL 10 ±3% 0.3µL ±2% 0.2µL 20 ± 2.2% 0.44µL ±1.5% 0.3µL P300 20 ±10% 2.0µL ±4% 0.8µL 150 ±2.5% 3.75µL ±0.8% 1.2µL 300 ±1.5% 4.5µL ±0.5% 1.5µL

Sterility

Full polycarbonate enclosure designed to limit exposure. The OT-2 is not a sterile environment

Add the Opentrons HEPA Module, or add your own UV lights

Viscosity

For best practices on automating viscous liquid handling, review our application note

-

API compatibility

- Interfaces with any product that has an API

- Opentrons software is open-source and users can make adjustments to the software as needed to interface with other products. While all integrations are possible, they all require custom code work i.e. most customers will need to write custom libraries and install software packages that are not shipped with the robot.

- Learn more ›

Interface

- Windows 10, macOS 10.10 or later, Ubuntu 12.04 or later.

- Opentrons App ›

Tip compatibility

- Use Opentrons Tips and Opentrons Filter Tips

- Opentrons guarantees the performance of Opentrons Tips which were specifically designed for the OT-2. The OT-2 was designed to accommodate all universal bore tip types, but tip quality and dimensions can vary significantly so third party tip performance cannot be guaranteed by Opentrons.

Labware compatibility

- Use common labware already in our Labware Library, or add your own

- If your labware fits on the OT-2 but is not in the Labware Library, it can be added by you using our Labware Creator, or by our team.

- Learn more ›

- OT-2 Manual ›

-

Warranty

- One year warranty against manufacturer defects

- Stress tested to last a minimum of 3 years of full-time use

- Learn more ›

Return Policy

- 60 day, 100% risk free

- Learn more ›

Certifications

- Certifications complete (CE, FCC, NRTL, CB, ISO 9001)

- Not certified/validated (IVD, GMP)

-

Tip Handling

- Pick up tip

- Drop tip

- Return tip

- New tip (always, never, once)

- More...

Liquid Control

- Aspirate

- Dispense

- Aspirate speed

- Dispense speed

- Blowout

- Touch tip

- Mix

- Air gap

Utility

- Move to

- Delay

- User-specified pause

- Homing

- Comment

Transfer

- Basic transfer

- Volumes > Pipette Volume

- Distribute

- Consolidate

Variable Settings

- Speed

- Volume

- Count

Other

- Dispose

Watch our pre-recorded demo video series.

This 4-part series covers OT-2 product basics in detail, and provides an overview of the Opentrons ecosystem.